Order management in wholesale distribution requires more than just tracking packages or updating spreadsheets. As more orders flow in and customer expectations become harder to meet, older processes start to fall short. A modern POS system for distributors steps forward as the backbone of order handling – no longer just a sales tool, but a central part of daily operations.

Used with purpose, it helps teams clear away distractions and prioritize what truly affects performance: accurate orders, fast turnaround, and consistent service. This article shares practical guidance for distributors looking to handle orders with greater clarity and control through their POS setup.

Highlights:

- A POS system supports effective order taking by allowing quick input of large orders, real-time stock visibility, mobile access, and automatic syncing across teams.

- Distributors should automate order processing, sort orders by urgency, and refine picking and packing to keep fulfillment fast and accurate.

How a POS system for distributors can take orders effectively

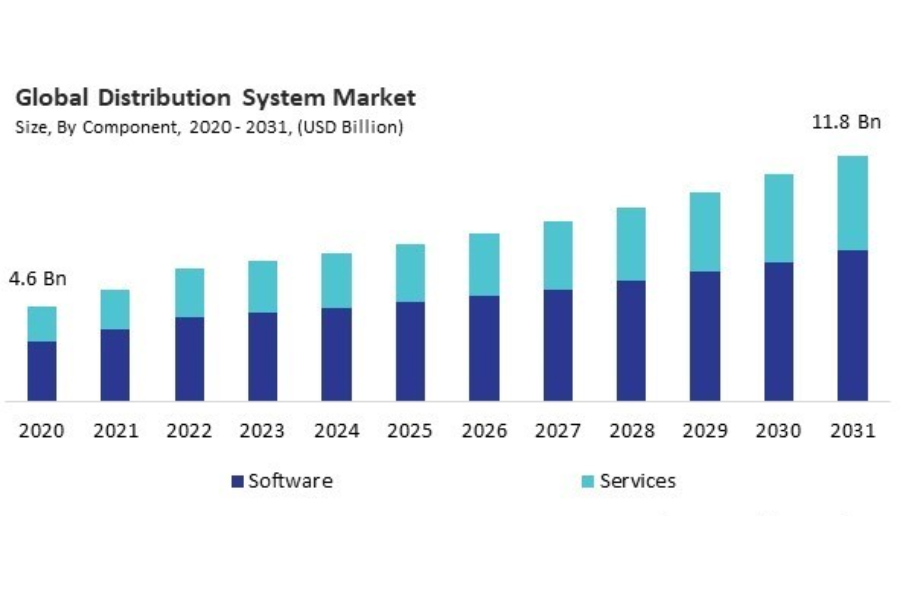

The global distribution system market is on track to reach $11.8 billion by 2031, driven by a 7.5% CAGR, reflecting increasing demand for faster, more connected infrastructure across the supply chain. This growth signals rising expectations for operational precision, real-time access, and smarter tools in distribution.

To keep pace, a POS system must be built for speed and clarity. Distributors can’t afford delays caused by complex screens or scattered data. Managing high volumes, varied client needs, and constant inventory shifts requires a system that keeps everything moving without adding friction. This is where the right POS becomes more than software; it becomes the engine of the operation.

- The system must match how the warehouse and field operate: That means quick access to customer pricing, live stock updates, and bulk order inputs without extra taps. Sales reps should punch in large orders while talking to clients—no guesswork, no waiting. The fewer screens, the better.

- Mobile access matters: Reps taking orders on the road need tools that load fast and work offline if needed. Syncing can happen in the background once a connection returns. The system should remember past orders, flag trends, and make it easy to reorder without starting from scratch.

- Payment flexibility also matters: Credit terms, part payments, and varying customer agreements are common in distribution. A system that handles those without calling head office keeps deals moving.

- Everything should connect. Once an order is placed, it should move to accounting, stock, and customer records without extra steps. No one should need to fix things later or repeat the work.

Best practices for efficient order handling of POS system for distributors

Automate order processing

Order processing becomes much smoother when routine tasks are automated. Things like confirming stock levels, generating invoices, or notifying customers can happen without manual input, allowing staff to focus on more pressing tasks.

Automation handles repetitive steps in the background, which not only saves time but also limits errors that may come from manual entry. As a result, orders move through the system faster, and operations run with greater consistency.

This approach of the POS system for distributors is particularly beneficial in a distribution setting where speed and accuracy are key. Once the manual tasks are taken off employees’ plates, they can address customer inquiries, resolve specific issues, or focus on orders requiring extra attention. This keeps the workflow continuous, speeding up the overall process and minimizing downtime.

Keep inventory data live

Keeping inventory data live is integral to order fulfillment. Inventory accuracy rates for stores typically range between 70% and 90%, while distribution centers often achieve rates of over 99.5%.

Keeping inventory data up to date with every sale, return, or shipment is necessary to prevent confusion. Having stock levels constantly updated secures that the items customers order are available and helps avoid situations where items are sold that aren’t actually in stock. This level of accuracy in real-time is vital for order fulfillment, as discrepancies in stock can lead to order delays or even cancellations.

When inventory updates occur in real-time, staff can operate confidently without the need to check stock manually. This reduces the chances of shipping errors and ensures that customers receive exactly what they ordered. As inventory data stays live, employees can focus on fulfilling orders, knowing that their data reflects the actual stock on hand.

►►► Optimal solution set for businesses: Multi store POS, Next-gen POS, Inventory Management Software (MSI), Self Service, Automation, Backorders

Sort orders by urgency

Prioritizing orders based on urgency is a proven strategy to improve operational efficiency and customer satisfaction. A McKinsey study found that implementing order prioritization and line allocation improved on-time, in-full (OTIF) delivery by 5 to 10 percent, highlighting the effectiveness of structured order handling.

Not every order carries the same weight when it comes to time sensitivity. Sorting orders based on factors like delivery deadlines, customer priority, or available stock helps distributors focus on what’s pressing first. When the system is set up to flag orders by priority, using tags, filters, or rules, staff can make sure that rush orders don’t get buried among less urgent ones.

Having this system in place prevents costly delays that can damage customer relationships. It allows staff to address urgent shipments first, while orders that can wait are handled later. This approach leads to smoother operations, making sure the most important orders are always sent out on time.

Refine picking and packing

In a busy distribution environment, speed and accuracy during the picking and packing stages are vital. Employees should be given clear, organized pick lists that minimize walking time and maximize order accuracy.

Using a layout that logically groups products together saves time and secures that each item can be located easily, reducing the chances of backtracking. This planning allows for quicker movement throughout the warehouse, so orders are filled faster.

Once items are picked, packing should follow a consistent process that minimizes mistakes. Standardized packing materials and proper labeling reduce the chances of mispackaged or damaged goods. By maintaining a set packing routine, the process flows quickly and reduces the risk of confusion or unnecessary delays in shipping.

Connect POS to other systems

Linking the POS system for distributors to other essential systems like inventory management, shipping, and accounting guarantees that all departments are on the same page. When sales are made, stock counts are updated automatically, and returns are logged without additional input. This keeps everything aligned and minimizes the chances of miscommunication, making the entire operation more cohesive.

This interconnected setup simplifies workflows by removing the need for duplicate data entry across systems. It keeps everything in sync, from inventory updates to financial records. The result is a smoother, more unified order process that doesn’t require constant back-and-forth between systems or departments.

Allow mobile POS use

A mobile POS system for distributors is a powerful tool for teams who need flexibility. The mobile POS market is projected to reach $5.63 trillion by 2027, with an estimated 1.9 billion global users by 2026.

With mobile devices, sales staff can access order details, check stock levels, and process sales from anywhere within the warehouse or on the road. This reduces the need for employees to return to a fixed station to complete tasks, allowing them to work more freely and serve customers on the go.

In environments where connectivity is spotty, mobile systems should function offline and sync data once a connection is restored. This means that no matter where the staff is, they can continue working and completing orders without disruption. The mobility provided by mobile POS keeps everyone moving, which improves the overall efficiency of the order fulfillment process.

Keep training simple and support steady

A POS system for distributors is only as effective as the people using it. Training employees should be straightforward and focused on the tasks they will use the system for most. Short videos, interactive training, and hands-on experience are more effective than lengthy manuals. Training should be closely aligned with everyday tasks to make learning quicker and more relevant to the job at hand.

Support shouldn’t end once the system is live. Staff will inevitably encounter issues or need assistance as they get more familiar with the software. Having quick access to support whether through chat, phone, or an easily searchable guide, helps resolve issues before they cause significant disruptions. A reliable support system is key to maintaining smooth operations over time.

New trends in POS system for distributors

New trends in POS system for distributors are shaping the future of sales and inventory management. These trends are making processes faster, more efficient, and customer-focused.

- Artificial Intelligence & Machine Learning: AI and machine learning are helping distributors improve inventory management and predict sales trends by analyzing data patterns. These technologies assist in automating processes and making smarter decisions based on real-time insights.

- Headless POS Architecture: Headless POS systems are gaining popularity due to their flexibility. By separating the front-end and back-end, businesses can integrate their POS system with e-commerce platforms and other tools, providing more customization and scalability.

- Sustainable POS Systems: With a growing emphasis on sustainability, many distributors are adopting POS systems designed to minimize energy consumption and reduce waste. This includes features like paperless transactions, digital receipts, and eco-friendly hardware options.

- POS Data Analytics: Data-driven insights are becoming a key feature of modern POS systems. By collecting and analyzing sales data, distributors can track trends, optimize stock levels, and tailor their marketing strategies to improve profitability.

- Cloud-based POS Systems: Cloud-based POS systems are providing distributors greater flexibility and scalability. These systems allow real-time data updates, remote access, and centralized management, making it easier for businesses to handle multi-location operations.

How ConnectPOS is an ideal POS for distributors

ConnectPOS is a custom-built POS for both retailers and wholesale distributors, aiming to manage inventory, sales, and customer relationships with clarity and speed. It works in sync with eCommerce platforms to support a unified operation. Real-time updates and B2B-focused functions support consistent performance and better decision-making.

- Omnichannel Wholesale Management: ConnectPOS links physical stores and digital platforms. Orders, inventory, and customer details are updated instantly, helping teams avoid duplication and delays. This coordination supports daily operations across all sales touchpoints.

- Flexible Pricing, Discounts & Quotation Management: The system allows different rates for specific customer groups. Bulk discounts and special deals can be applied automatically. Customers can request quotes directly within the platform, cutting down on manual exchanges.

- Multi-Store & Warehouse Management: One dashboard handles several store and warehouse locations. Teams receive live stock updates, can transfer goods easily, and get alerts when supplies run low, helping maintain smooth inventory flow.

- Advanced B2B Wholesale Features: ConnectPOS is wholesale POS that supports customer-specific pricing, automated purchase orders, and account-based sales rep management. Managers can assign reps and track their performance through the system.

- Smooth Integration with eCommerce Platforms: This POS system for distributors works with Magento, Shopify, and BigCommerce. It also connects with third-party tools for ERP, CRM, accounting, and warehouse systems, keeping all business data aligned.

- Mobile POS and Cloud-Based Solution: Teams can access POS functions on tablets or smartphones. Cloud access allows remote monitoring of performance. Offline mode supports uninterrupted sales even during internet outages.

FAQs: POS system for distributors

How can a POS system for distributors help manage large volumes of orders?

A POS system gives real-time access to sales and inventory updates. This helps teams stay on top of order flow, avoid duplication, and handle high demand without confusion.

What kind of reporting does a POS system provide?

Reports give insight into sales patterns, staff performance, and order timing. This helps managers make informed decisions about what to stock or when to scale.

How do returns and refunds work in a POS setup?

Returns can be processed directly through the POS with reference to the original sale. This helps track stock going back into inventory and updates customer records instantly.

Conclusion

Disconnected systems result in common issues like missed orders, confusion, and inventory gaps. A POS system designed for distributors effectively manages high order volumes, tracks stock levels in real time, and prevents fulfillment errors. It connects sales teams, warehouse staff, and back-office operations through a single platform. When integrated into daily operations with proper training and updates, it transforms from mere software into a vital part of the business mindset.

For wholesale distributors ready to take control, ConnectPOS is built to support smarter order handling every step of the way. Contact us now!

►►► Optimal solution set for businesses: Shopify POS, Magento POS, BigCommerce POS, WooCommerce POS, NetSuite POS, E-Commerce POS