Backorders influence sales planning, supplier coordination, and customer expectations, and they often highlight how well a company manages its resources. Many retailers misunderstand the concept, seeing it only as a problem, while in reality, it can reveal product strength and market demand.

This article from ConnectPOS examines what does backorder mean and why the term carries more weight than a simple stock status update. Understanding what backorder truly means helps clarify how businesses can turn this situation into a strategic opportunity rather than a roadblock.

Highlights:

- A backorder means a customer places an order for an item that’s temporarily out of stock but will be delivered once available.

- To prevent backorders, track inventory levels closely, improve supplier lead times, and use demand forecasts to plan ahead more accurately.

What Does Backorder Mean?

A backorder means a product you’ve ordered isn’t currently in stock, but the seller expects it to be available soon and will send it to you when it arrives. Businesses use backorders to continue selling an item that’s temporarily out of stock, allowing customers to reserve the product while the seller waits for new inventory to be produced or delivered. It’s a way to fulfill demand and keep customers engaged, even if there’s a waiting period.

Backorders are more than just “items temporarily unavailable.”. They highlight gaps in supply and demand, making them an important signal for retailers and suppliers to refine inventory planning, manage customer expectations, and strengthen delivery processes.

How Backorders Work

When asking what does backorder mean, it refers to situations where a business accepts requests and sometimes payments for items not currently in stock. Those requests are recorded as backorders. Once accepted, the inventory system converts them into purchase orders and forwards them to the right internal team, supplier, or distributor. Buyers are then given an expected delivery timeframe along with details on how payment will be processed.

Retailers may instruct suppliers to ship items directly to customers, or they may first receive the goods, translate the backorders into sales orders, and then send the items after charging the customer’s account when required.

For a limited range of products and a manageable order volume, this process remains straightforward. Difficulties arise when the volume of backordered items grows or when retailers depend on manual processes, requiring each purchase order to be matched to a sales order before fulfillment can be completed.

Backorders vs. Out of Stock

Both terms signal unavailability at the moment of purchase, yet they carry very different implications for the buyer.

An item placed on backorder is expected to return, with suppliers or distributors confirming that replenishment is in progress. This means the order will eventually be fulfilled, though the delivery window extends beyond normal shipping times. Out-of-stock items, on the other hand, carry no such certainty. They may or may not return to the catalog, leaving customers with no clear timeline for availability.

Backordered products introduce a waiting period for the buyer, often longer than standard delivery cycles, but the purchase remains secured and the item will be shipped once supply is restored. Out-of-stock listings close off that option entirely, making backorders a more reliable path for customers who are willing to wait for a guaranteed delivery at a later date.

►►► Optimal solution set for businesses: Multi store POS, Next-gen POS, Inventory Management Software (MSI), Self Service, Automation, Backorders

How Backorders Affect Supply Chains?

Understanding what does backorder mean is crucial because backorders create extra strain on supply chains. They require suppliers and manufacturers to handle more than their usual production or procurement levels. Meeting these requests means sourcing or producing additional units alongside regular inventory needs. If capacity falls short, the pressure moves further up the chain, or retailers are left with the option of canceling pending orders.

Backorders can slow down the supply chain and create a ripple effect (bullwhip effect), forcing suppliers and retailers to constantly adjust their ordering plans. The farther a company is from the source of the backorder, the less visibility it has into the reasons behind the demand spike.

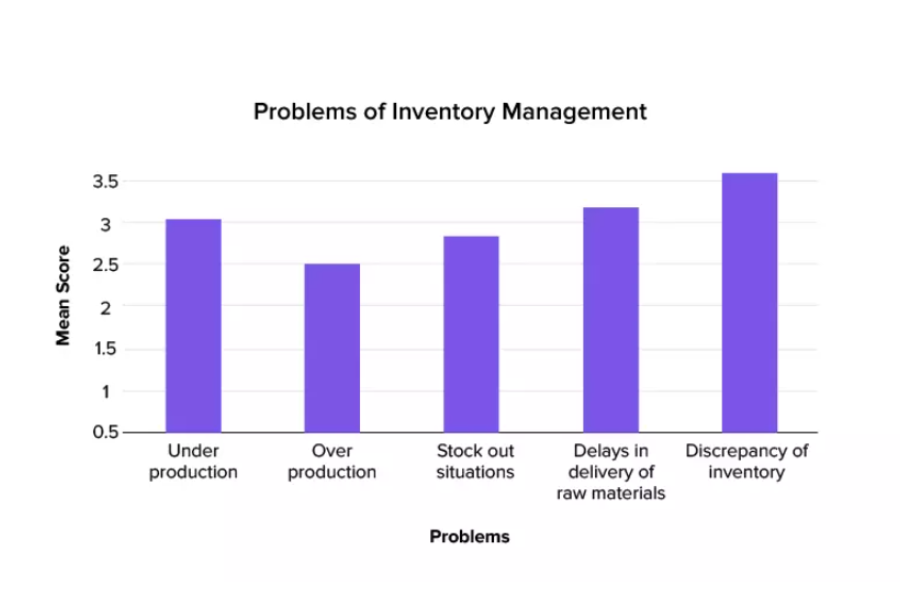

In addition, one study found that internal factors, such as inaccurate inventory records (mean score 3.08) and delayed deliveries from suppliers (mean score 2.68), also make backorder issues worse, extending processing times and increasing pressure across the entire chain.

For example, an international supplier may not realize that a major local festival temporarily increased the demand for decorative lights. To prevent stockouts, they might expand production, which raises costs throughout the supply chain and leaves retailers with surplus inventory once the celebration ends.

The Way to Account for Backorders

Even when inventory systems are in place, knowing clearly what does backorder mean is important because backorders often call for separate handling in both accounting and customer communication. Buyers need clear updates on the status of their orders, when charges will occur, and the delivery timeline.

Backlogs are usually recorded as a subset of sales, expressed either in dollar value or by the number of units ordered. Instead of being recognized as completed sales, they remain classified as backorders so that records stay accurate if an order is canceled or if supply cannot be secured. Once the products are available, the company either ships them directly to the customer or arranges for drop-shipping. At that point, the transaction is recorded as finalized.

Monitoring backorder performance is part of tracking inventory metrics such as forecast accuracy and supplier lead time. One key measure is the backorder rate, which indicates how much of total demand comes from items placed on backorder. It is calculated using the following formula:

Backorder Rate = (# of delayed orders from backorders ÷ total orders placed) × 100

Pros and Cons of Backorders

Backorders can signal demand and free up cash flow but also risk customer frustration and operational strain. Viewing them as a strategic tool rather than a problem can turn them into a growth opportunity instead of lost sales.

Advantages of Backorders

Positive reasons to allow backorders include creating more sales opportunities and building flexibility for smaller businesses. Other advantages include:

- Offers market insights: Backorders work like customer feedback, showing which products attract demand and when shoppers want them most.

- Improved cash flow: Businesses that avoid carrying excess stock cut storage costs and keep more money available for other needs; in some sectors, less inventory also lowers tax obligations.

- Minimizing storage: Lower storage requirements and fewer inventory-related expenses come from not holding extra goods.

Disadvantages of Backorders

Shoppers facing backorders may disengage from future purchases: 45 percent of first-time buyers abandon a purchase when faced with a backorder, while 70 percent of shoppers will switch to a competitor if required to wait. Backorders can also create risks that lead to lost revenue or customer dissatisfaction. These include:

- Losing out on business: Some customers do not want to wait and may cancel their purchase in favor of a competitor.

- Loss of market share: Consistent backorders or long wait times can push customers toward other brands, eroding loyalty.

- Increased complexity: More backorders mean more chances of service problems such as handling expired payment methods or delivery changes.

- Inventory carrying costs as a pivot point: A company selling small, low-cost, stable-demand items may afford to stock more, while one dealing in large appliances risks tying up capital, storage space, and obsolescence, making backorders a more sensitive choice.

How to Prevent Backorders?

Even with inventory systems in place, preventing backorders requires more than just tracking stock levels. When backorders do happen, they often require separate handling in both accounting and customer communication, but avoiding them upfront is a more efficient approach.

Here are a few ways to reduce the risk of backorders:

Use demand forecasts to guide purchasing decisions

Analyze past sales trends, seasonal patterns, and marketing plans to predict demand more accurately and adjust inventory orders accordingly.

Monitor supplier performance and lead times

Delays often begin upstream. Build relationships with reliable suppliers, and keep an eye on lead time changes so you can adjust your replenishment schedule if needed.

Set reorder points and safety stock levels

Automate reordering with stock thresholds that kick in before items run too low. Safety stock acts as a buffer during demand spikes or supply delays.

Sync inventory across all sales channels

If you’re selling on multiple platforms, make sure inventory updates in real time to avoid overselling products that are no longer available.

Plan for peak seasons in advance

High-volume periods like holidays or product launches can stress your inventory. Lock in supplier commitments and bulk orders ahead of time to prevent stockouts.

How ConnectPOS Helps Businesses Manage Backorders

ConnectPOS backorder software equips businesses with tools to keep sales active and inventory under control even when items run low.

With real-time updates and seamless integration across ERPs, CRMs, and email marketing platforms, ConnectPOS ensures that every backorder is tracked accurately. Teams can prioritize fulfillment, notify customers proactively, and adjust inventory strategies based on actionable data, helping businesses maintain trust and improve overall operational efficiency.

- Stock monitoring and alerts: Stay informed of low inventory with real-time alerts and vendor-based forecasts that help plan restocking and maintain steady lead times.

- Order handling and delivery: Build confidence with automated order tracking, clear notifications for customers, and proactive steps to handle risks during fulfillment.

- Storefront coordination: Link several sales channels and connect systems with third-party tools through HTTP requests, keeping all locations updated and aligned.

- Customer-focused sales: Allow backorder purchases, track buyer behavior, group customers for targeted campaigns, and create timely promotions to encourage purchases.:

- Dynamic communication: Send tailored messages at key points of the buying journey, update customers on stock status, and increase conversions with cart alerts and shipping details.

- Product presentation: Create detailed product pages with backorder buttons, descriptions, delivery timelines, and stock indicators to keep buyers informed and engaged.

- Data and analysis: Collect and study customer actions to send personalized messages, re-engage inactive buyers, and drive repeat purchases.

- Integration with external platforms: Integrate with powerful platforms Google Merchant, Google Sheets, and ERPs such as NetSuite, BrightPearl, Cin7, Spark Shipping, and other systems. Link loyalty programs, CRMs, and email marketing tools to maintain real-time updates, track orders, and keep information flowing across teams.

FAQs – What Does Backorder Mean

Why do backorders happen?

Backorders often arise from unexpected demand spikes, supply chain delays, or deliberate inventory strategies such as just-in-time (JIT) stocking. They may also occur when suppliers face production setbacks or when logistics disruptions affect delivery schedules.

Are backorders always a negative sign?

Not necessarily. In some cases, backorders indicate strong demand or the success of marketing campaigns. They can show that certain products are highly valued by customers. The main risk comes from poor management of the balance between supply and demand.

What does backorder mean compared to out of stock?

A backorder means the product is temporarily unavailable but can still be ordered and will be shipped once it is restocked. Out of stock means the product cannot be ordered because there is no inventory and no confirmed restock date.

What does backorder mean for delivery time?

Backorders usually lead to longer delivery times because the item will only be shipped after the supplier receives new stock. Delivery dates can vary depending on restocking schedules.

Conclusion

Backorders show more than just numbers on an inventory sheet; they reveal the balance between demand and supply. For anyone asking what does backorder mean, it’s not just about delayed items. It’s a signal that, when handled well, can support stronger customer communication, steady cash flow, and smarter production planning.

If your business wants to manage backorders with accuracy and gain clear visibility across channels, ConnectPOS provides tools that keep orders moving and customers informed. Contact ConnectPOS to see how backorder management can become a growth driver for your operation.

►►► Optimal solution set for businesses: Shopify POS, Magento POS, BigCommerce POS, WooCommerce POS, NetSuite POS, E-Commerce POS