Retail continues to shift under pressure from changing buyer behavior, logistical demands, and service expectations. Meeting these shifts takes more than small fixes, it requires systems that tie inventory clarity to execution speed. A Point of sale system inventory management helps link transaction data to operational response. For future-readiness, retailers are turning to setups that support real-time stock visibility, transactional accuracy, and cross-channel selling.

This article looks at how retail trends are reshaping inventory practices at the point of sale. Customer demands, fulfillment agility, and varied sales channels now call for smarter tools at checkout. A POS inventory management setup with live data and channel coordination supports that shift. We’ll explore how trends like omnichannel models, mobile payments, and predictive stock handling align with systems built for real-time response and control.

Highlights:

- A point of sale inventory management system plays a strategic role by connecting sales, stock, and customer data to drive faster decisions and leaner operations.

- With the right POS inventory tools, retailers can adapt to trends like omnichannel selling, mobile payments, personalized offers, and smarter demand planning.

The Strategic Role Of Point Of Sale System Inventory Management

For manufacturers, wholesalers, and multi-channel retailers, inventory is a dynamic asset that influences cash flow, customer experience, and operational agility. In this landscape, the point of sale (POS) system plays a strategic role not just at the transaction level, but across the entire inventory lifecycle.

- Sales and Inventory Connection: POS inventory functions as a connective tissue between purchase transactions and stock adjustments. Each sale automatically triggers data updates that reflect real-time inventory movement. This interaction supports demand forecasting and aligns purchase planning with actual depletion trends.

- Centralized Inventory Oversight: When inventory is tracked across online platforms, physical stores, and warehouses, a point of sale system inventory management solution allows the entire network to work with the same dataset. This coordination helps avoid duplication, shortens response time to out-of-stock events, and supports cross-channel fulfillment needs like BOPIS.

- Role in Production Management: Manufacturers gain traceability through component-level tracking embedded in the POS system. When linked to ERP or MRP platforms, the data flow aligns customer demand with production capacity. This setup supports job costing accuracy and improves clarity in material allocation.

- Governance and Inventory Auditing: POS systems bring structure to inventory oversight. Barcode-based tracking, permission-restricted access, and automated reconciliation processes limit human error and support policy enforcement. Data logs contribute to audit readiness and meet the documentation standards required for compliance or third-party review.

- Inventory Intelligence for Decision-Making: POS platforms aggregate real-time indicators such as turnover velocity, dormant stock levels, shrinkage rates, and supplier fulfillment history. These metrics support tactical decisions regarding procurement, pricing, and product lifecycle planning, eliminating the need for manual reporting.

Future Retail Trends You Can Incorporate With POS Inventory Management

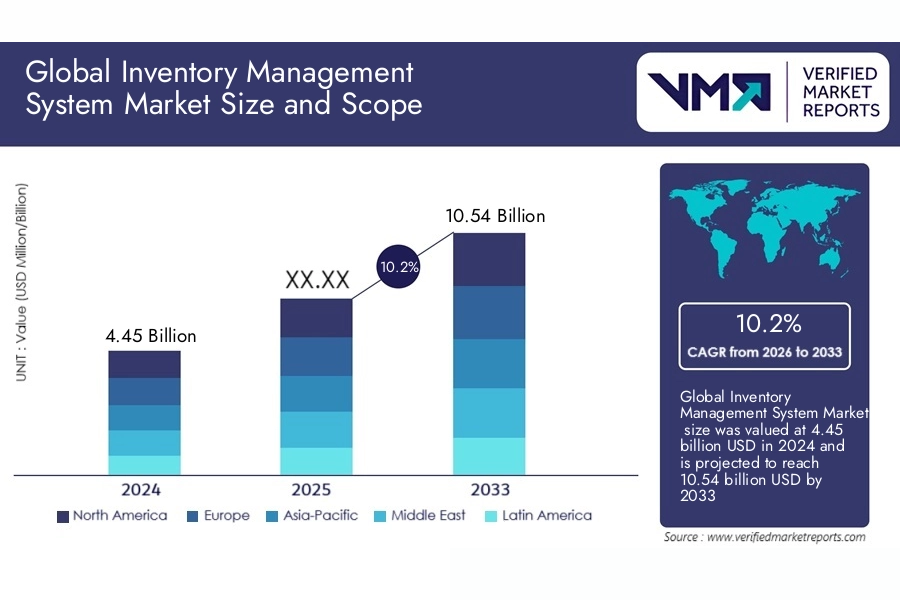

The inventory management system market is projected to grow from USD 4.45 billion in 2024 to USD 10.54 billion by 2033, reflecting an expanding focus on retail responsiveness. This trajectory reflects how retailers are moving toward more dynamic, connected systems.

Research by McKinsey highlights a wide range of logistics technologies helping retailers shift how they track and manage stock. When aligned with POS systems, these tools support a closer link between demand signals and inventory availability, improving timing and coordination.

This section examines the retail developments that are actively transforming inventory management at the transaction level. These shifts involve more than just the adoption of new technologies. They reflect more profound changes in customer behavior, fulfillment expectations, and the structure of supply chains.

Omnichannel Retailing

Retail businesses are transitioning toward unified commerce models, where customers expect to browse, purchase, and return products across multiple platforms without friction. Point of sale system inventory management plays a structural role in this shift by maintaining synchronized inventory records across brick-and-mortar locations, e-commerce stores, and third-party marketplaces.

When these data sets align, it becomes possible to fulfill online orders from physical stockrooms, provide real-time availability for click-and-collect services, and shift unsold goods across channels based on regional demand.

For retailers operating in fragmented environments, omnichannel consistency reduces sales lost to stockouts and enables more intelligent resource allocation. A POS system that captures every stock movement at the transaction level provides the traceability required to balance inventory loads, avoid overstock in low-performing areas, and accelerate sell-through in higher-traffic regions. This allows for quicker reaction to trends and deeper insight into how purchasing behaviors differ by channel.

Mobile-First and Contactless Transactions

Customers are increasingly expecting sales interactions to happen on handheld devices, at kiosks, or through contactless payment methods. Point of sale system inventory management is adapting to this expectation by integrating with mobile devices that provide instant stock checks, flexible checkout points, and touch-free transactions. These capabilities reduce physical queuing, free up sales staff to assist customers throughout the store, and increase the number of purchase points, all without adding fixed terminals.

►►► Optimal solution set for businesses: Multi store POS, Next-gen POS, Inventory Management Software (MSI), Self Service, Automation, Backorders

For inventory tracking, the shift to mobile POS means data flows in faster and from more locations. Whether a sale occurs via tap-to-pay at a pop-up or through a tablet on the showroom floor, the transaction immediately adjusts available inventory. This visibility is beneficial for temporary sales events or traveling vendors, where stock levels must be watched closely. The ability to act on real-time updates supports agility in pricing, merchandising, and replenishment planning.

Hyper-Personalization and Loyalty

Retailers are expanding their focus on loyalty programs, personalized programs, and customer-specific pricing as a way to build longer-term relationships. Point of sale system inventory management provides the infrastructure for these initiatives by connecting SKU-level sales data with individual shopper profiles. Purchase history, frequency, and category preference can inform targeted discounts or early access to limited stock, programs that drive retention and increase lifetime value.

When inventory systems are informed by personal buying patterns, businesses can more accurately plan product assortments and marketing campaigns. For example, if a customer consistently buys a specific product line, the system can alert staff when restocks arrive or when similar items are introduced. This level of targeting adds relevance to promotions and reduces the likelihood of excess inventory by aligning product supply with actual shopper interest.

Demand Forecasting and Smart Replenishment

Retailers are placing increasing focus on aligning inventory supply with near-term sales patterns. POS inventory management enables smarter replenishment strategies by recording item-level sell-through rates and flagging fluctuations tied to specific times, channels, or promotions.

These records inform demand modeling systems, which support short-cycle forecasting built on transactional history rather than assumptions. When integrated with supplier lead times, it becomes easier to adjust purchasing quantities based on projected turnover, seasonal variability, or promotional lift.

More retailers are shifting away from fixed replenishment cycles in favor of flexible restocking triggered by predictive thresholds. A Point of sale system inventory management that tracks velocity at the SKU level allows teams to respond to changes in buying behavior as they occur, not just during monthly reviews. This data-centric model minimizes aging inventory, reduces the likelihood of excess on slow-moving items, and enhances readiness for demand spikes. The outcome is a tighter alignment between what’s stocked and what’s expected to sell.

Agile Fulfillment and Delivery Options

Retailers are adopting fulfillment methods that prioritize speed, convenience, and flexibility, from in-store pickup to local courier dispatch. POS inventory systems serve as the foundation for these capabilities by maintaining up-to-date stock availability across locations.

This supports fulfillment logic that can allocate orders to the nearest stocked location, prevent overselling, and notify staff immediately when items are committed to a pickup order. Retailers that link inventory and fulfillment workflows can deliver more accurately and faster across formats.

As fulfillment options diversify, inventory movement becomes more complex. POS systems help maintain accountability by logging transfers, stage completions, and status updates within a unified view. Whether goods are picked from the floor, pulled from the backroom, or packed for last-mile delivery, every touchpoint is timestamped. This traceability reduces internal friction, supports customer communication, and creates transparency for both operations teams and shoppers tracking their orders.

Data-Driven Operations

Retail performance is increasingly shaped by operational decisions grounded in live analytics. Point of sale system inventory management contributes to this transformation by collecting and centralizing data around stock rotation, sell-through timelines, markdown triggers, and supplier reliability.

These inputs power dashboards that inform purchasing, merchandising, and marketing teams in real time. Instead of reacting to outcomes, retailers can shift toward proactive adjustments based on patterns emerging from the floor.

When decision-makers have access to these metrics, it becomes easier to spot margin leakage, identify dead stock, or reallocate inventory across locations based on regional trends. The POS system becomes a feedback loop between what is being sold and what is being stocked. Over time, this results in cleaner assortments, faster turnover, and tighter margin control, all outcomes that support long-term viability in competitive retail sectors.

ConnectPOS – Empowering Future-Ready Retail

Inventory management today must account for fragmented fulfillment models, high SKU complexity, and variable lead times. Businesses juggling multiple locations, warehouses, or supply partners require more than basic stock tracking. They need a system that intelligently coordinates stock across all sources in real time. ConnectPOS delivers this through its built-in Multi-Source Inventory (MSI) capability designed to support dynamic retail workflows across both brick-and-mortar and online operations.

Rather than treating inventory as a single pool, ConnectPOS allows each warehouse, storefront, and drop-ship partner to function as an independent stock source. This flexibility supports agile delivery strategies while maintaining central control over inventory rules, thresholds, and availability.

Key Functions Driving Retail Agility

- Real-time multi-location synchronization: ConnectPOS updates inventory status instantly across all points of sale and fulfillment centers, reflecting transfers, reservations, or order changes without delay.

- MSI-enabled stock orchestration: Assign inventory rules based on location, priority, or region. ConnectPOS routes orders to the most appropriate source based on stock availability, customer location, or fulfillment logic.

- Intelligent inventory control: Customizable stock thresholds, restock alerts, and forecasting help improve purchase timing and reduce carry costs. MSI settings allow each source to operate independently while syncing with a unified backend.

- Unified order and fulfillment management: Whether fulfilling from warehouse, store, or third-party supplier, ConnectPOS tracks source-level fulfillment status and provides a single view of customer order progress.

- Location-aware analytics:Generate location-specific reports on inventory turnover, backorders, and fulfillment rates. These insights support better procurement planning and operational decisions.

- Scalable, API-first architecture: Built for compatibility with modern eCommerce POS platforms and ERP systems, ConnectPOS supports both B2C and B2B models with real-time syncing and modular deployment options.

ConnectPOS is the point of sale system inventory management with MSI equips retailers and manufacturers with the infrastructure to handle distributed inventory operations without sacrificing speed or accuracy, positioning them to meet the demands of today’s hybrid commerce landscape.

FAQs: Point of Sale Inventory Management

What role does a Point of sale system inventory management play in aligning with omnichannel expectations?

A POS system ties together stock records across online and offline sales points. That connection supports availability accuracy, unifies purchase data, and helps maintain consistency across every buying experience.

How does a POS system support mobile-first and contactless preferences?

Transaction handling moves beyond the counter when mobile capabilities are active. This setup accommodates payment flexibility and allows staff to finalize sales anywhere in-store while keeping stock counts current.

Can POS inventory tools contribute to demand prediction?

The system gathers real-time sales behavior and transactional history, which feed forecasting models. These insights help buyers and planners align procurement volume with expected shifts in product movement.

How does POS inventory management accommodate flexible delivery setups?

Retailers can configure fulfillment rules based on customer proximity, store capacity, or warehouse timelines. This setup supports ship-from-store models and in-person pickup workflows without disrupting internal supply coordination.

What kind of data insights can a POS system provide for daily operations?

The dashboard captures stock aging, return trends, shrinkage rates, and supplier lead time. These data points help buyers detect gaps, adjust order volumes, and compare supplier consistency over time.

Conclusion

Retail demands continue to shift under pressure, such as more data, faster expectations,and fewer margins for error. Inventory systems tied to the point of sale system inventory management must keep pace. They do more than move products through checkout; they connect demand signals to available stock, fulfillment routes, and upstream supply decisions.

The future belongs to retailers who align execution with visibility. That alignment depends on systems built for speed, clarity, and control. ConnectPOS provides that structure. It helps retailers handle complexity, scale across channels, and respond to real-time shifts with precision. To explore how ConnectPOS supports forward-looking retail, reach out and take the next step.

►►► Optimal solution set for businesses: Shopify POS, Magento POS, BigCommerce POS, WooCommerce POS, NetSuite POS, E-Commerce POS