Smooth distribution starts with smart inventory management, and POS manufacturers are at the heart of making it happen. They design systems that help businesses track stock in real time, streamline order fulfillment, and keep operations running efficiently. This article breaks down how POS technology improves inventory control and boosts distribution performance.

Highlights:

- POS manufacturers build systems that help businesses manage inventory, streamline distribution, and stay aligned across sales channels.

- Key features include real-time stock tracking, automated restocking, multi-location management, and integration with eCommerce and logistics platforms.

Understanding POS Manufacturers and Their Offerings

Who Are POS Manufacturers?

POS manufacturers in this context refer to companies that develop software solutions designed for transaction management, inventory control, and customer engagement. Unlike hardware producers, these companies focus on building digital platforms that cater to different industries, such as retail, hospitality, and service-based businesses.

These software providers create systems that handle various functions, from processing payments to integrating loyalty programs and generating reports. Some platforms are designed for small businesses, while others support large enterprises with complex requirements. The right choice depends on factors such as business size, operational model, and future growth plans.

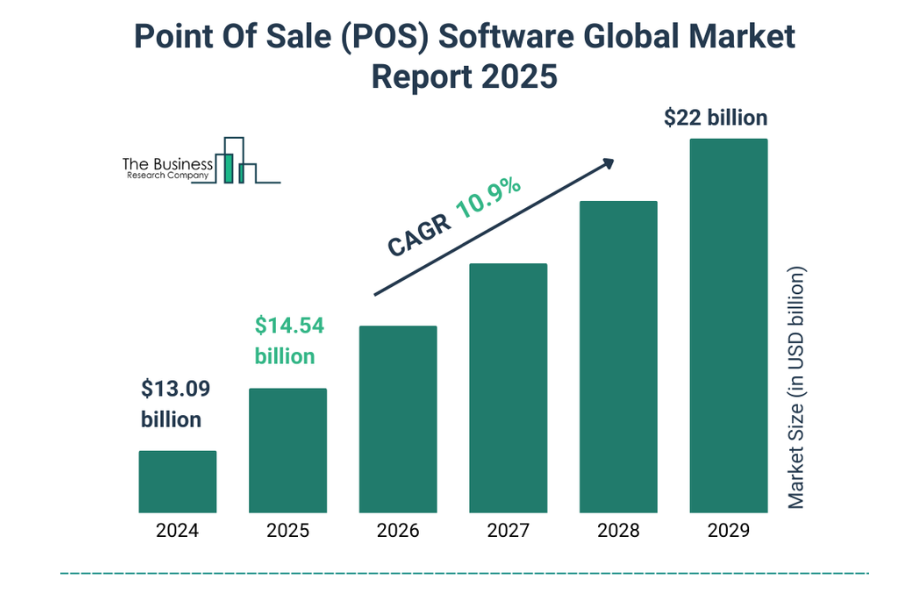

The Point of Sale (POS) software market has experienced rapid expansion, driven by key players like Square, ConnectPOS, and Shopify. In 2024, the market is valued at $13.09 billion and is expected to reach $14.54 billion by 2025, reflecting an 11.1% compound annual growth rate (CAGR).

This growth has been fueled by factors such as the early adoption of smartphones, limited access to traditional POS systems, the rise of cloud-based solutions, government efforts to promote cashless transactions, and the increasing popularity of mobile payment apps and app stores.

Core Products & Technologies

POS manufacturers develop a range of systems to support different business needs. Some of the key offerings include:

- Cloud-based POS systems – Web-based platforms that allow businesses to access sales data, manage inventory, and process transactions from any location with an internet connection.

- On-premise POS software – Installed directly on a company’s local servers, often preferred by businesses that require full data control and offline functionality.

- Omnichannel POS platforms – Designed to integrate both online and physical store transactions, helping businesses maintain a consistent customer experience across different sales channels.

- Industry-specific POS solutions – Software tailored for specific sectors such as restaurants, retail stores, and salons, incorporating features relevant to their daily operations.

- AI-driven analytics and reporting – Data analysis tools that help businesses identify trends, track sales performance, and make informed decisions based on customer behavior.

Selecting the right POS software depends on how well it aligns with business needs. Factors such as scalability, ease of integration, and compatibility with existing systems play a key role in making an informed decision.

How POS Manufacturers Optimize Distribution And Inventory Management Efficiency

POS manufacturers play a direct role in helping businesses manage inventory more accurately and distribute stock more efficiently. Their systems bring together automation, data, and real-time visibility to support better decisions and faster execution.

Now, let’s look into into the details.

Innovative Methods for Tracking Inventory

POS manufacturers create systems that help businesses track stock levels with greater accuracy. Barcode scanning, RFID technology, and cloud-based tracking tools allow retailers to monitor inventory movement in real time.

►►► Optimal solution set for businesses: Multi store POS, Next-gen POS, Inventory Management Software (MSI), Self Service, Automation, Backorders

These systems reduce manual input and show actual stock levels in real time, so teams can respond faster to changes in demand. Predictive tools built into the software also analyze sales history to help businesses prepare for shifts in buying patterns, reducing both excess stock and shortages.

Automation That Connects the Dots

Linking POS systems with warehouse tools, accounting platforms, and supplier networks helps businesses move faster and with fewer errors. Automated order processing shortens the time between a sale and restocking, while reducing the need for manual tracking.

Real-time updates between online stores and physical locations help teams avoid overselling and improve stock accuracy. Alerts and forecasting tools also help align purchasing with actual demand, cutting down on guesswork and improving response time.

Industry-Specific Systems That Match Day-to-Day Operations

Different industries require different workflows, and POS manufacturers build systems that reflect those needs. A retailer managing multiple store locations has different inventory challenges than a restaurant managing ingredients and table service.

In retail, features like barcode scanning, automatic restocking, and supplier connections are key. For hospitality, tools for recipe tracking and order coordination are more relevant. These systems give each business type the control it needs to adapt quickly and stay organized during busy periods.

A system that fits the business model makes it easier to manage growing orders, expanding product lines, and changing supply needs, whether the business runs a single outlet or operates across regions.

Faster Order Processing with Fewer Errors

Order fulfillment depends on speed and precision, making it a key focus for POS software developers. A system that integrates real-time inventory updates prevents overselling and stock discrepancies. Businesses that rely on manual tracking often experience delays and errors, leading to customer dissatisfaction and operational setbacks.

Automation plays a major role in improving accuracy. When a purchase is completed, stock levels adjust instantly, alerting staff to reorder when supplies run low. This reduces the risk of understocking high-demand products or overstocking slow-moving items. Some systems also support predictive ordering, analyzing past sales data to forecast demand.

Processing speed directly affects customer experience. A system that supports quick transactions, barcode scanning, and digital payment options helps businesses serve customers without unnecessary delays. By reducing wait times and eliminating errors, businesses can improve service quality and strengthen customer loyalty.

Managing Stock Across Various Locations and Sales Channels

Order accuracy and turnaround speed can shape the entire customer experience. POS systems that sync live with inventory data help eliminate stock mismatches and prevent overselling.

When a purchase is made, the system adjusts stock levels instantly and triggers restock alerts when quantities drop. This keeps popular products available and helps avoid tying up space with low-demand items. Some platforms also support smart reordering, using past sales to predict what products will be needed next.

Checkout speed matters, too. POS features like barcode scanning and digital payments help reduce wait times and give customers a smoother experience, while also supporting staff to move quickly without errors.

Read more: Manufacturing POS engineered for business efficiency

Data-Driven Decisions for Supply Chain and Logistics

POS manufacturers build systems that turn transaction data into useful insights. This helps businesses fine-tune purchasing decisions, track product movement, and adjust inventory based on real trends.

By reviewing sales history, businesses can identify fast-moving items and flag products that don’t sell as quickly. This helps teams decide when to restock or when to run a promotion to move older inventory.

Some POS platforms also link with shipping and logistics partners, making it easier to track deliveries and adjust plans when delays happen. This keeps warehouse and store teams informed and reduces disruption.

Organizing stock based on demand helps speed up picking and packing. Products that sell frequently can be placed together, while slow-moving items can be marked down or removed. With better data, teams can plan more effectively and reduce waste across the supply chain.

ConnectPOS – A Key Player in Distribution And Inventory Management Efficiency

Efficient inventory management and streamlined distribution are crucial for businesses to stay competitive in the fast-paced retail environment. ConnectPOS is a powerful solution that optimizes order fulfillment, synchronizes inventory in real time, and integrates seamlessly across multiple sales channels.

- Real-Time Inventory Synchronization: ConnectPOS updates stock levels instantly across all sales channels, including brick-and-mortar stores, warehouses, and online platforms. This prevents overselling, reduces stock discrepancies, and improves overall inventory accuracy.

- Smooth Order Fulfillment & Smart Automation: With ConnectPOS’s Order Fulfillment System, businesses can manage orders across multiple locations with click-and-collect (BOPIS), ship-from-store, and dropshipping. Automated stock replenishment prevents shortages, while AI-powered analytics assist with demand forecasting. Customizable reports help track sales and inventory for smarter decisions.

- Omnichannel Selling and Distribution: ConnectPOS integrates with leading eCommerce POS platforms like Shopify, Magento, and BigCommerce, ensuring smooth coordination between online and offline sales. Customers enjoy a seamless shopping experience, and businesses can efficiently manage multiple warehouses and fulfillment centers.

- Scalability and Flexibility: Whether you’re a small retailer or a global distributor, ConnectPOS adapts to various business models, supporting B2B, B2C, and hybrid sales strategies.

FAQs: POS Manufacturers

What role do POS manufacturers play in optimizing distribution?

POS manufacturers develop systems that integrate with warehouses, supply chains, and sales channels, ensuring seamless order fulfillment and inventory synchronization.

What are the key technologies used by POS manufacturers?

POS manufacturers integrate AI-driven analytics, IoT-enabled inventory tracking, barcode/RFID scanning, and cloud computing to enhance distribution efficiency and optimize stock control.

How do POS manufacturers support omnichannel retail?

They develop POS solutions that sync online and offline sales, allowing businesses to manage inventory seamlessly across eCommerce platforms, warehouses, and physical stores.

Conclusion

POS manufacturers play a direct role in helping businesses stay organized and move products efficiently. With real-time inventory tracking, automated restocking, and connected systems across locations and channels, retailers gain better control over daily operations. Instead of chasing errors or reacting to delays, they can make faster decisions, reduce excess stock, and keep shelves consistently aligned with demand. The result isn’t just fewer mistakes – it’s a smoother, more responsive supply chain built to support long-term growth.

Looking for a reliable solution? ConnectPOS provides the tools you need to manage inventory and streamline distribution. Visit contact ConnectPOS to learn more and see how it can support your business.

►►► Optimal solution set for businesses: Shopify POS, Magento POS, BigCommerce POS, WooCommerce POS, NetSuite POS, E-Commerce POS