Inventory serves as the foundation of manufacturing performance. Without clear oversight of parts, stock levels, and supply availability, production schedules falter and fulfillment becomes unpredictable. Software tailored for this sector goes beyond basic recordkeeping; it provides real-time insight, supports material handling decisions, and connects the shop floor to procurement and distribution. This article reviews six systems shaped by the day-to-day requirements of manufacturers. Each inventory management software for manufacturing addresses common gaps in parts tracking, purchasing workflows, and location coordination. These tools help teams keep orders accurate and adjust supply plans as demand evolves, reflecting the operational pressures that define manufacturing today.

Highlights:

- Unlike retail, manufacturing inventory spans raw materials to finished goods, requiring tighter control over production stages, material flow, and work-in-progress.

- The right inventory management software should handle BOMs, production planning, system integrations, and forecasting, all while scaling with your operations and keeping teams in sync.

What’s The Difference Between Managing Inventory For Retail & Manufacturing

Managing inventory for retail and manufacturing varies in terms of the type of inventory, objectives, and systems used. Retail primarily deals with finished goods for consumer sale, while manufacturing handles raw materials and the production process.

- Inventory Type: Retail inventory management focuses on finished goods that are ready for consumer purchase. In manufacturing, the inventory includes raw materials, work-in-progress (WIP), and completed products that are part of the production chain.

- Purpose: Retail management centers on maintaining a steady supply of finished products to meet consumer demand and drive sales. In contrast, manufacturing inventory management focuses on efficiently managing materials across various stages of production.

- Systems: Retailers use POS and stock control systems to track sales, restocking, and product movement. Manufacturing relies on ERP and MRP systems to manage the entire production workflow, including the tracking of raw materials and the management of work-in-progress.

- Focus: Retail inventory management focuses on forecasting demand, stock availability, and the speed of product turnover. Manufacturing inventory management focuses on synchronizing material flow with production schedules and monitoring product quality at various stages.

- Process Complexity: In retail, inventory management is primarily concerned with the stock of finished products. Manufacturing, on the other hand, involves a more detailed process that tracks raw materials, components, work-in-progress, and final products throughout the entire production cycle.

Overall, retail focuses on managing finished goods, whereas manufacturing requires more detailed tracking of raw materials throughout the production stages. This is where inventory management software for manufacturing becomes essential. It supports this complexity by aligning materials, labor, and timelines, enabling better control and adaptability across the supply chain.

Key Features To Look For In Manufacturing Inventory Software

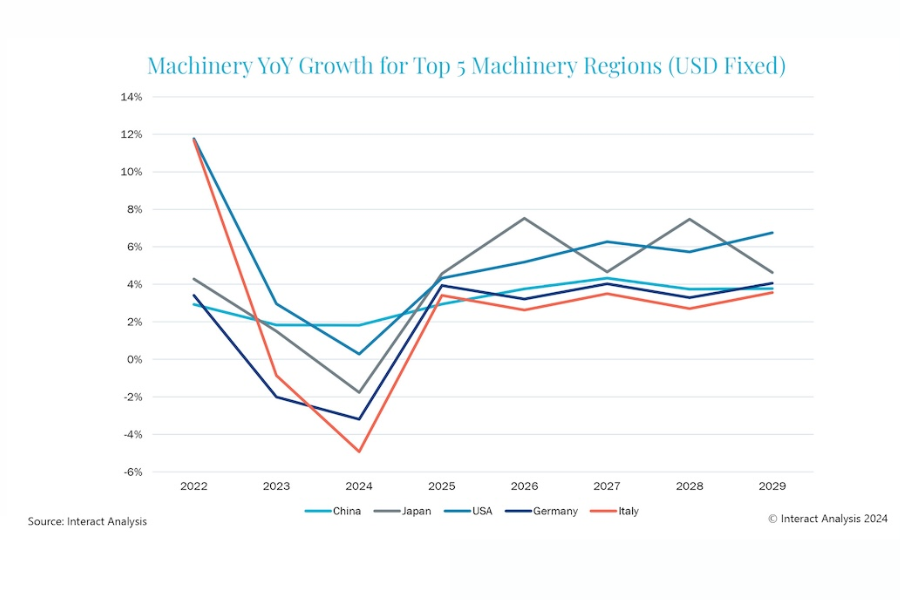

Manufacturing operations depend on structured processes, accurate inventory visibility, and clear coordination across departments. In a climate where Interact Analysis anticipates modest growth of 0.6% in 2024 followed by stronger expansion beyond, selecting inventory software becomes a strategic move.

Success hinges on aligning the platform with production goals, available resources, and shifting customer needs. The inventory management software for manufacturing must support this trajectory through core functionality that reflects operational depth and manufacturing complexity.

Key Features include:

- Real-Time Inventory Tracking: This function maintains up-to-date records of material movement across locations. It supports better material availability and lowers the chances of overstock or missed production due to missing components.

- Bill of Materials (BOM) & Work Order Management: Bill of Materials (BOM) should support detailed hierarchies, substitutions, and multi-level assemblies. Work order tracking helps assign resources, follow routing stages, and monitor progress from raw input to finished product.

- Production Planning and Scheduling: This supports load balancing across machines, labor shifts, and production lines. It helps maintain delivery timelines and adjusts production priorities when changes arise.

- ERP, MRP, and Accounting Integration: Connection with broader business systems helps bring together procurement, costing, inventory, and sales data. It supports better traceability across finance and operations.

- Demand Forecasting and Reporting: Forecasting tools use historical data and purchasing trends to anticipate future material needs. Strong reporting functions allow operations teams to analyze production costs, inventory turnover, and supplier performance.

- Scalability and Cloud Access: As businesses expand or diversify their product lines, the system should support added workflows, users, and data volume. Cloud access brings broader collaboration and supports remote coordination across teams and manufacturing sites.

Top 6 Best Inventory Management Software For Manufacturing In 2025

ConnectPOS

ConnectPOS is a manufacturing-focused POS solution designed to support production workflows, inventory control, and sales operations in one unified platform.

Built with Microservices, API-first, Cloud-native, and Headless architecture, it adapts to the evolving demands of manufacturers, whether handling B2B, B2C, or multi-channel sales. ConnectPOS helps manage inventory in real time, automate order processing, and maintain continuity across the factory floor and fulfillment centers.

Main Features:

- Real-time inventory and “always-on” mode to maintain uninterrupted sales and accurate stock levels, even during connectivity issues.

- Integration with ERP systems to maintain consistent data across manufacturing, sales, and supply chain operations.

- BOM (Bill of Materials) support, allowing integration into the POS system to align with accounting and tax compliance requirements.

- Customizable workflows and role-based access for large-scale manufacturing teams.

- Support for both B2B and B2C transactions across wholesale, retail, and direct sales models.

- Mobile POS capabilities to take orders, check inventory, and process payments anywhere on the factory floor or at off-site locations.

Advanced reporting and analytics tools for visibility into sales performance, inventory movement, and operational health. - Personalized pricing, quoting, and multi-currency payments to support global customers and bulk transactions.

- Security-first approach with encrypted transactions and permission controls for sensitive information.

- Seamless integration with eCommerce platforms, CRMs, accounting tools, payment gateways, and hardware devices.

Pricing:

►►► Optimal solution set for businesses: Multi store POS, Next-gen POS, Inventory Management Software (MSI), Self Service, Automation, Backorders

Starts at $39 per month. Pricing may vary based on business size, number of users, integration complexity, and customization needs. A tailored quote is typically provided after consultation to align the platform with manufacturing-specific requirements.

MaintainX

MaintainX’s parts inventory management system provides tools to track stock and spare parts in an organized, timely manner. Low stock alerts enable teams to respond proactively before shortages occur. These notifications support the accurate creation of purchase orders and improve timing by helping maintenance departments estimate reorder points.

This inventory management software for manufacturing provides clear reporting, offering insight into which items are used most frequently. This clarity helps teams estimate future costs and assess when to restock. Each withdrawal from inventory can be scanned using a QR or barcode reader, automatically updating the system and logging the movement of each item on the floor.

Every transaction leaves a searchable record, building a transparent inventory log. Comments and images can be added to the document to explain why an adjustment was made, helping teams maintain context over time.

Key Features:

- Low inventory alerts

- Inventory reporting and usage tracking

- QR and barcode scan support

- Searchable part history with documentation

Pricing:

- Basic: $0 per user/month (lifetime use)

- Essential: $21 per user/month

- Premium: $59 per user/month

- Enterprise: Custom plan based on business size and requirements

UpKeep

UpKeep’s inventory management software for manufacturing simplifies tracking and managing spare parts. Technicians can quickly generate barcodes for inventory items, making work order updates efficient. Stock thresholds trigger alerts when parts run low, and inventory counts are automatically updated with each work order. The system provides real-time visibility, reducing overordering and emergency shipments.

Mobile access allows teams to view historical records, and data visualisations highlight cost trends for better decision-making. Purchase orders are easily created and tracked, streamlining procurement tasks.

Key Features:

- Barcode generation for inventory tracking

Minimum stock level alerts - Real-time inventory updates linked to work orders

- Purchase order creation in PDF format

- Data visualisation to track costs and trends

- Remote access to historical records via a mobile app

Pricing:

- Lite: $20 per user/month

- Starter: $45 per user/month

- Professional: $75 per user/month

- Business Plus: Custom pricing available; free trial is accessible upon request

Fiix

Fiix’s inventory management software helps manufacturing companies track and manage parts efficiently. It simplifies purchasing with minimum stock alerts, integrates with CMMS and ERP systems, and guarantees inventory accuracy.

The system enables quick part location, usage tracking, and real-time reporting to support informed decision-making. The built-in FIFO system and predictive analytics guide ordering and inventory management.

Key Features:

- Inventory purchasing and management

- Integration with CMMS and ERP systems

- Inventory tracking and reporting

Pricing:

- Free trial: $0

- Basic: $45 per user/month (one month free with annual billing)

- Professional: $75 per user/month (one month free with annual billing)

- Enterprise: Custom pricing available upon request

Limble

Limble’s inventory management software for manufacturing helps maintenance teams stay organized and manage spare parts efficiently. Teams can quickly check stock, part locations, and depletion dates through barcode scanning. Push and email notifications keep users updated when inventory changes, ensuring real-time awareness.

Inventory tracking, reporting, and forecasting help teams monitor part usage and costs. Reports are automatically generated to provide insights into which parts were used, while forecasting allows teams to anticipate future needs. Custom workflows for inventory purchasing prevent excess or outdated stock by automatically sending orders to vendors.

Key Features:

- Inventory organization and management

- Tracking, reporting, and forecasting

- Barcode lookups

- Push and email notifications

- Custom inventory purchasing workflows

Pricing:

- Free trial: Limited functionality

- Standard: $28 per user/month ($23 per user/month with annual subscription)

- Premium: $69 per user/month ($59 per user/month with annual subscription)

- Enterprise: Custom pricing available upon request

eMaint

eMaint helps small manufacturing businesses manage inventory more effectively, saving time and reducing costs. The software allows for easy tracking of spare parts, assigning work orders, and controlling inventory levels. It helps prevent stock shortages and overspending by setting minimum stock thresholds. Spare parts can also be requested and shared between facilities, making it easier to manage resources across different locations.

Inventory reporting provides insight into the entire organization, allowing teams to identify slow-moving parts and make informed decisions. The platform’s mobile app keeps teams connected, ensuring smooth operations across multiple worksites.

Key Features:

- Tracking and assigning spare parts to work orders

- Reorder management and threshold setting

- Dashboards for slow-moving parts

- Purchasing and sharing spare parts across locations

- Mobile app for organization-wide connectivity

Pricing:

- Team: $69 per user/month

- Professional: $85 per user/month

- Enterprise: Custom quotes available upon request.

FAQs: Inventory Management Software for Manufacturing

Is there inventory management software that integrates easily with ERP or existing production systems?

ConnectPOS and eMaint support integration with major ERP platforms such as SAP and Oracle, as well as production management software to ensure seamless data flow.

Which software is suitable for small and medium-sized manufacturing businesses (SMEs)?

MaintainX and UpKeep are popular choices for small to mid-sized manufacturers due to their user-friendly interfaces and quick implementation without complex setups.

Do these software solutions support real-time inventory tracking?

Yes. ConnectPOS, Fiix, and Limble all support real-time inventory tracking, helping manufacturers monitor materials and components throughout the production process.

Conclusion

Each inventory management software for manufacturing reviewed reflects a different path toward inventory control in manufacturing. Some prioritize forecasting and automation, while others center on equipment compatibility or sales coordination. For production-driven teams, the key is choosing a system that fits their operational pace and responds to shifting market demands.

Improved visibility, fewer stock discrepancies, and faster reaction times emerge when the right system is in place. This allows manufacturers to depend less on guesswork and more on precise, accessible data.

For manufacturers seeking a retail-ready POS system that integrates directly into their production environment, ConnectPOS brings sales and inventory together within one architecture. To explore how it fits your workflow, request a demo or speak with a ConnectPOS consultant today.

►►► Optimal solution set for businesses: Shopify POS, Magento POS, BigCommerce POS, WooCommerce POS, NetSuite POS, E-Commerce POS